stretch wrap machine repair near me Services That Extend Machine Life

Wiki Article

All Regarding Stretch Wrap Machine Repair Service: Important Tips for Preserving Your Tools

Keeping a stretch Wrap Machine is necessary for ensuring its effectiveness and longevity. Regular examinations and attending to common issues can stop pricey downtime. Comprehending the Machine's components and carrying out routine upkeep techniques are vital actions. Many operators ignore the nuances of troubleshooting and correct training. What are the most effective techniques for keeping your equipment in top shape? Exploring these critical facets can lead to more dependable operations and less unforeseen failures.Understanding the Components of Stretch Wrap Machines

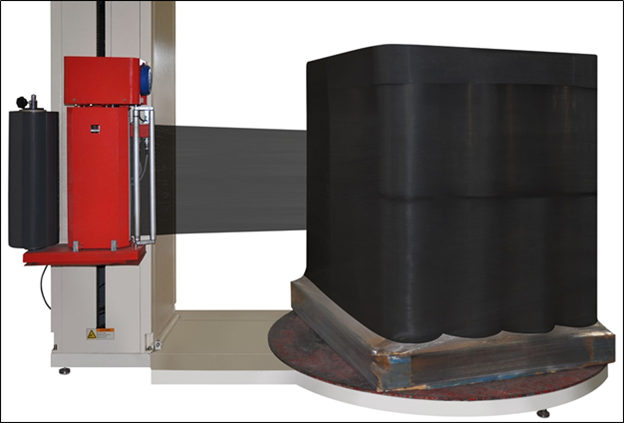

Stretch Wrap devices are important devices in product packaging procedures, created to safeguard products on pallets for storage space and transport. Understanding their components is fundamental for reliable upkeep and procedure. Secret components consist of the movie carriage, which gives the stretch film, and the turntable or arm that revolves the lots for even covering. The control panel allows drivers to adjust settings such as stress and speed, making sure ideal covering conditions. Additionally, the power supply is essential for the Machine's operation, while the framework provides structural honesty. Sensors are also incorporated to discover tons size and change wrapping appropriately. Each component plays a considerable duty in the total performance of the Machine. Routine experience with these components can assist operators in troubleshooting and regular maintenance, avoiding downtime and ensuring constant efficiency in the product packaging process. Understanding these components is the initial action to guaranteeing long life and reliability in stretch Wrap devices.Common Issues and Their Solutions

In any type of packaging operation, issues with stretch Wrap equipments can develop in spite of a solid understanding of their elements. One common issue is inconsistent wrapping stress, which can lead to under- or over-wrapped loads. Changing the stress setups or checking the film feed can frequently rectify this problem. Another frequent issue is movie tearing, commonly caused by low quality material or incorrect handling. Changing to higher-quality movie and guaranteeing proper filling strategies can assist stop this. Additionally, Machine jams may happen due to particles or misalignment. Frequently looking for blockages and ensuring that elements are properly straightened can reduce this danger. Electric failures can interrupt operations; checking links and changing damaged elements is vital. Addressing these typical problems promptly can improve Machine efficiency and lengthen devices life expectancy, ultimately making certain reliable packaging processes.Routine Upkeep Practices

Regular upkeep methods are necessary for the longevity and effectiveness of stretch Wrap equipments. A daily examination checklist, a well-defined lubrication timetable, and clear part replacement standards are important elements of this maintenance routine. Executing these practices can aid protect against unanticipated malfunctions and ensure smooth procedure.Daily Evaluation Checklist

Regular examinations of the stretch Wrap Machine are crucial for ensuring peak efficiency and durability. A daily examination checklist need to consist of vital elements to keep an eye on. First, drivers ought to check the movie tension and alignment to avoid unequal wrapping. Next off, the Machine's electric connections need to be analyzed for wear or damages, as defective wiring can cause operational failings - stretch wrap machine repair near me. In addition, the belts and rollers must be checked for any kind of signs of deterioration, making certain smooth activity. Verify that safety and security guards are in location and functioning appropriately. By sticking to this everyday list, operators can recognize potential issues early, decreasing downtime and prolonging the life of the stretch Wrap Machine. Constant inspections eventually contribute to trustworthy and efficient operationsLubrication Arrange Significance

Often neglected, a well-structured lubrication schedule plays a critical function in the upkeep of stretch Wrap makers. Routinely applying the appropriate lubricating substances to vital elements lowers friction, lessens wear, and boosts overall performance. This proactive method not only prolongs the life-span of the equipment but also ensures regular efficiency, reducing the possibility of unexpected failures. Operators ought to stick to the producer's suggestions regarding lubrication periods and kinds of lubes to utilize. Keeping track of lubrication degrees and observing any modifications in Machine operation can supply beneficial insights into prospective concerns. Inevitably, an attentive lubrication schedule is important for keeping performance and integrity in stretch Wrap makers, adding substantially to operational performance and cost-effectiveness.Component Replacement Standards

Troubleshooting Tips for Quick Repairs

When encountering concerns with a stretch Wrap Machine, swift troubleshooting can considerably minimize downtime and improve performance. Operators must first speak with the Machine's handbook for certain error codes or signs. An usual concern is improper stress; adjusting the stress setups can often fix irregular covering. Checking for blockages or ensuring the movie is packed effectively is essential.Another constant issue is the Machine delaying if the film try this web-site is not feeding correctly. In this case, evaluating the electrical connections and fuses might reveal issues. Frequently oiling relocating parts can prevent mechanical failures, while making sure that all parts are aligned will enhance performance. Additionally, keeping track of the Machine for unusual noises can provide early cautions of potential breakdowns. Implementing these troubleshooting steps can result in quick repairs, reducing disruptions in operations and maintaining reliable operations.When to Seek Expert Aid

When to seek professional assistance for a stretch Wrap Machine is crucial for preserving operational performance, identifying. Signs such as uncommon sounds or vibrations, regular movie breakage, and irregular Wrap stress can suggest underlying concerns that need professional attention. Resolving these problems quickly can avoid further damages and assure the Machine runs smoothly.Unusual Sounds or Vibrations

Uncommon noises or resonances from a stretch Wrap Machine can indicate underlying issues that may jeopardize its performance. These abnormalities often recommend imbalance, used parts, or not enough lubrication, all of which can result in even more significant problems if left unaddressed. Operators must check the Machine carefully for any adjustments in noise or resonance patterns, as this can offer critical understanding into its problem. If the noises are consistent or the vibrations are extreme, it is recommended to seek professional aid. Disregarding these indication may result in expensive repair work and downtime. Routine assessment and maintenance can mitigate dangers, however when doubtful, getting in touch with a professional ensures the Machine runs successfully and safely.Regular Film Breakage

Regular movie damage in a stretch Wrap Machine can signify underlying problems that call for instant attention. Operators must initially check out the film quality, ensuring it satisfies the Machine's specifications. Worn or incorrectly mounted movie rollers might additionally add to the issue, bring about boosted tension and movie stress. Additionally, imbalance of the Machine elements can worsen breakage, showing try here the requirement for realignment or substitute of components. If these basic checks do not fix the issue, it may be time to consult an expert technician. stretch wrap machine repair near me. Specialist treatment can identify more complex troubles, such as motor breakdowns or software program concerns, guaranteeing the Machine operates efficiently and successfully. Prompt specialist help can protect against additional damage and expensive fixings

Irregular Wrap Tension

Inconsistent Wrap tension can result in improper tons security and increased material waste, making it a considerable problem for stretch Wrap Machine operators. This problem frequently emerges from devices malfunction, such as damaged components or incorrect calibration. Operators must monitor stress very closely, as rising and falling degrees can compromise the stability of covered tons, leading to damage during transport or storage space. It might indicate deeper mechanical issues if changes to the Machine setups do not resolve the concern. Looking for expert assistance is recommended when there are persistent incongruities, as seasoned specialists can diagnose and fix underlying problems that might not be immediately noticeable. Prompt treatment can not only recover ideal efficiency yet also expand the life of the stretch Wrap Machine.Ideal Practices for Avoiding Devices Failures

While routine maintenance is necessary for making certain the longevity of stretch Wrap makers, applying ideal practices for protecting against tools failings can significantly improve their dependability. Initially, operators must stick to a rigorous schedule for regular assessments, concentrating on crucial parts such as equipments, motors, and belts. Keeping track of efficiency metrics, consisting of Wrap tension and speed, can aid recognize potential concerns prior to they escalate.Additionally, making certain that the Machine is utilized within its specified ability can minimize excessive stress and anxiety on components. Training staff on proper procedure strategies is crucial, as incorrect use can lead to early wear or damage.Regularly cleansing the Machine to remove particles and dirt can additionally improve efficiency. Finally, keeping a well-documented upkeep log permits far better tracking of repair services and can assist in recognizing persisting issues. By complying with these ideal methods, firms can considerably lower the danger of unanticipated equipment failures.Often Asked Concerns

Exactly how Commonly Should I Replace Stretch Wrap Movie?

The frequency of stretch Wrap film replacement relies on usage, ecological variables, and movie high quality. Commonly, companies examine film stability on a regular basis, replacing it when signs of wear or damage end up being obvious to assure peak performance.Can I Make Use Of Non-Standard Film With My Stretch Wrap Machine?

Utilizing non-standard movie with a stretch Wrap Machine may lead to compatibility concerns, affecting efficiency and potentially creating damage (stretch wrap machine repair near me). It is a good idea to consult the Machine's specs and maker standards before attempting to use alternative moviesWhat Are the Indicators of Wear in Stretch Wrap Machine Elements?

Indicators of wear in stretch Wrap Machine components include unusual noises, irregular wrapping stress, noticeable damage to components, getting too hot, and enhanced downtime. Routine evaluations and upkeep can help recognize these issues prior to they rise right into significant troubles.Exist Specific Cleaning Products Recommended for Upkeep?

The question of suggested cleaning products for upkeep frequently develops. Specialized degreasers and non-corrosive services are commonly suggested, ensuring efficient cleaning without damaging sensitive elements, consequently lengthening the equipment's life-span and maintaining ideal performance.Exactly How Does Moisture Impact Stretch Wrap Efficiency?

Moisture significantly affects stretch Wrap performance, affecting its adhesion and stress. High humidity can result in decreased stick buildings, while reduced humidity might cause brittleness, ultimately jeopardizing the stability and efficiency of the covered products. In any kind of packaging procedure, concerns with stretch Wrap machines can emerge regardless of a strong understanding of their parts. Constant movie damage in a stretch Wrap Machine can indicate underlying issues that call for instant interest. Irregular Wrap stress can lead to incorrect tons security and enhanced product waste, making it a significant problem for stretch Wrap Machine drivers. Using non-standard movie with a stretch Wrap Machine may lead to compatibility concerns, impacting efficiency and possibly creating damages. Signs of wear in stretch Wrap Machine parts include uncommon noises, inconsistent wrapping stress, visible damage to components, getting too hot, and increased downtime.Report this wiki page